IF WE simulate in 3D before surgery, could we reduce patient risk?

Studies estimate the annual number of deaths due to medical errors in the hundreds of thousands, so there is great incentive to revise the way the medical profession gains knowledge and experience. Advances in 3D printing technology and virtual simulation are creating new opportunities to improve the quality of treatments and patient safety.

French startup advances healthcare safety with 3D-printed organs

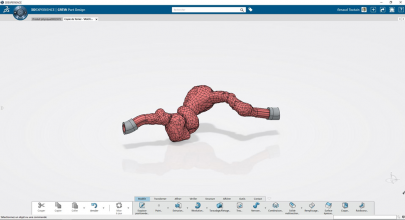

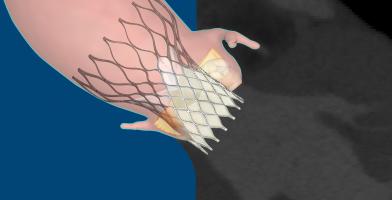

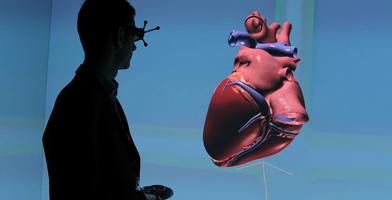

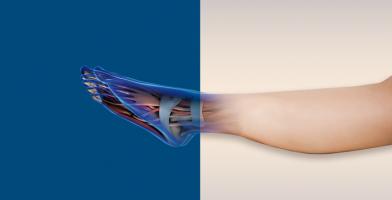

Biomodex’s mission is to use advanced software and 3D printers to fabricate cardiovascular and neurovascular life-like organs that can be used for medical training and pre-operative preparation to improve healthcare quality. Whereas other sectors have embraced 3D technology and simulation to optimize and predict real-life behavior, the medical industry has yet to fully take advantage of these advances, relying more on cadavers, mannequins and animals to revolutionize approaches to healthcare.

Biomodex targets three main areas:

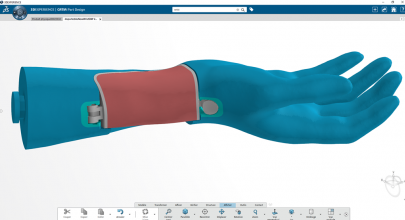

• Education: providing medical students with a catalog of virtual 3D models and 3D-printed organs to practice surgical procedures either through simulation or with life-like organs whose properties are similar to the real thing.

• Pre-op preparation: using MRI images or scans of a patient´s deficient organ to reproduce its exact twin, texture and thicknesses, allowing doctors to know what to expect and to perfect a surgical procedure before a live operation.

• Medical device manufacturers: adding simulation and 3D printing capability to their implants to help providers increase first-time-right surgical success.

BIOMODEX’S SUSTAINABLE DEVELOPMENT GOALS 🌍

Biomodex ensures healthy lives and promotes well-being for all and builds resilient infrastructure, promote sustainable industrialization and foster innovation. Their innovation will help improve health care safety by enabling practitioners and medical students to acquire knowledge and experience without putting patients at risk.

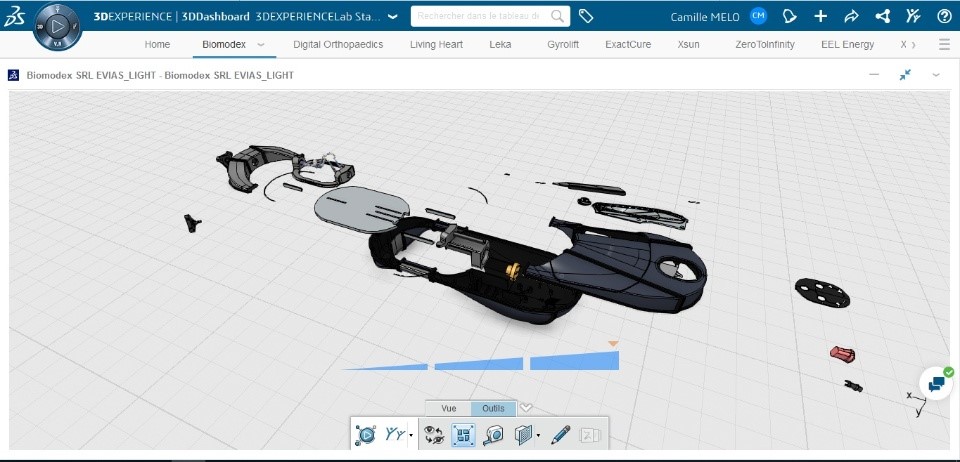

BENEFITS TO USE 3DEXPERIENCE® PLATFORM ON CLOUD

Biomodex has been involved in the 3DEXPERIENCE Lab program since 2015. The 3DEXPERIENCE Lab provides Biomodex with access to its FabLab. The Biomodex team leverages the Dassault Systèmes´ applications for organ design and for the manufacture of its first prototypes.

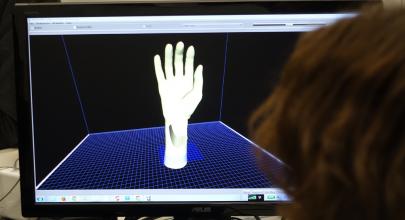

Using data obtained through organ imaging via an MRI or scanner, Biomodex developed a process that helps automate the creation of a virtual 3D model of that organ, which can then be printed using a 3D printer.

PLAY 3DEXPERIENCE

Meet the team

Founded by Thomas Marchand, business school graduate and Sidarth Radjou, engineer, Paris-based Biomedical Modeling Expertise, or Biomodex, covers the entire surgical value chain from raw patient data derived from CT scans or MRI to the manufacture of high-quality 3D-printed organs. The company closely works with medical experts to ensure that their models faithfully represent the characteristics of each organ.

-

Thomas MarchandCo-Founder & CEO

Thomas MarchandCo-Founder & CEO -

Sidarth RadjouCo-Founder & CTO

Sidarth RadjouCo-Founder & CTO -

Armand DoluiCPO

Armand DoluiCPO -

Pierre-Benoît PirlotCDO

Pierre-Benoît PirlotCDO

Collaboration

Biomodex was selected by the 3DEXPERIENCE Lab because of the innovative potential of its solutions for billions of people around the world. Dassault Systèmes supports Biomodex providing it with Cloud access to its design and simulation software and helping it transition to this environment. It also created a community on the 3DEXPERIENCE platform to facilitate interaction and the exchange of ideas between project members, medical experts and people passionate about this technology. The 3DEXPERIENCE Lab also proposes mentoring and training sessions to help Biomodex engineers use its solutions in the best way. The 3DEXPERIENCE Lab was involved throughout the entire value chain from generating a cloud of points, to constructing the 3D virtual model, and during simulations to test material resistance and zones where the organ is most fragile. Biomodex also has at its disposal a dedicated space on the 3DS campus with a FabLab and 3D printers to prototype their designs. The Lab´s help to industrialize the entire process saved Biomodex considerable time.

Similar projects

Submit your project

Do you think your project is the next big thing?

Join the team !