IF WE have a working environment for production-ready innovation, can we transform the future factory?

Aerospace companies are in the vortex of turbulent times.The speed and skill with which they adopt to the tumult will determine their fate. How can we help your aerospace company deliver more affordable products faster? How can you more efficiently integrate simulation and certification at every phase of a program to reduce costs and minimize risk? How can you manage the complexity of new materials, systems, personalization and manufacturing innovations in the context of both existing and new programs?

Accelerating Aerospace Innovation

A new Innovation Campus at Wichita State University.

Dassault Systèmes 3DEXPERIENCE® Center has been developed in partnership with Wichita State University’s National Institute of Aviation Research (NIAR), to establish an interconnected community of top researchers, corporations and laboratories to accelerate innovation. The Innovation Campus will consist of 29 buildings located on 120 acres, including 9 partner buildings, with Airbus already occupying the first.

Accelerate concept to takeoff up to 50% leveraging the Dassault Systèmes 3DEXPERIENCE® Center Network.

The 3DEXPERIENCE® Center Network includes facilities and teams across the globe. The first center is a 22,000 ft2 facility located on the Innovation Campus at WSU designed to accelerate Aerospace companies’ (from startups to established OEMs) ability to innovate from initial requirements through production and into operations while facilitating certification the entire time.

Located within the Experiential Engineering Building (EEB), the 3DEXPERIENCE® Center will enable companies to engage in advanced product development and the manufacturing of next-generation materials and technologies, with key components:

- 3DEXPERIENCE® platform

- Customer Collaboration Rooms

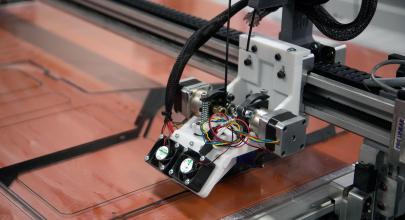

- Additive Manufacturing

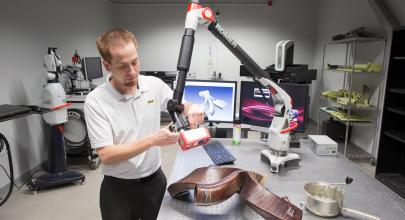

- Reverse Engineering and Inspection

- Virtual Reality & Immersive Technologies

- Multi-Robotics Advanced Manufacturing (MRAM)

Bringing together the virtual and the real, the 3DEXPERIENCE® Center delivers unique capabilities to accelerate the innovation from concept to take-off.

- Customer Collaboration Rooms allow teams up to 8 people across all functions to work together in one place on a single platform. These rooms include high resolution screens, web conferencing and other collaboration tools along with the full suite of solutions from Dassault Systèmes.

- Virtual Reality Technologies deliver experiences as they are being designed. Explore new designs in fully immersive 3D and see the results of multiple simulations including bird strikes, multi-physics analysis and many others.

- Additive manufacturing allows engineers to create custom parts as well as optimize standard parts for cost and weight – typically resulting in a 70% or more reduction in cost and weight.

- Multi-Robotics Additive Manufacturing (MRAM) makes it possible to explore any shape without restriction and reduce material waste up to 90 percent as well as optimize manufacturing techniques using the latest in robotics. MRAM can 3D print chopped fiber composite, mill, scan and execute many other advanced manufacturing techniques to accelerate production, lower the number of parts and eliminate manufacturing waste.

- Reverse Engineering and Inspection allows engineers to scan complex parts to create new virtual representations as well as to inspect new parts for certification and quality control.

Collaborative and collective Intelligence

Thanks to the 3DEXPERIENCE® platform, Aerospace companies will also be able to work together simultaneously across multi disciplines to bring new innovations to life. Now program managers, engineers, manufacturers, testers and suppliers, together at every stage of the program, can understand design tradeoffs, manufacturing constraints and program impacts.

Through the Innovation Campus, your company can take advantage of a number of solutions to accelerate the pace of innovation across a program:

- Experience the power of the 3DEXPERIENCE® Platform (1 day). Explore the power of the 3DEXPERIENCE® platform to accelerate your company’s ability to innovation.

- Workshop (3-5 days). Work with WSU and Dassault Systèmes experts to solve one of your toughest engineering challenges by leveraging the capabilities of 1 of the 25 labs

- 3DEXPERIENCELab Incubator (3-6 months). Create a dedicated space and 3DEXPERIENCE® platform for your team and access to the 25 labs in the EEB including the 3DEXPERIENCE® Center.

- Engineering Services. Contract to outsource engineering work to WSU/NIAR. To leverage their expertise in a key area, including testing, simulation, or other engineering work.

- Next Generation Fundamental & Applied Research. Companies can partner with WSU to research ways to solve a company’s toughest technical challenges.

- Join the Innovation Campus. Learn how your company can engage with this this vibrant community over the long haul to transform how you innovate.

Similar projects

Submit your project

Do you think your project is the next big thing?

Join the team !