If we automate textile handling, can we make the textile industry more sustainable?

We simplify complex manual labor into streamlined automation.

BREAKTHROUGH IDEA

At sewts, we are bridging one of the last gaps of automation and opening up entirely new spheres of application for robotics. By providing robots with human-like perception skills, we make the automatic handling of easily deformable materials possible. Our mission is to simplify complex manual labor into streamlined automation. Why can humanity shoot rockets into space, but some of the most repetitive work is still done manually? This is the idea behind sewts. We’re developing software that combines commercial robots, grippers and cameras into an intelligent system to enable the automation of processes - such as the handling of textiles - that were previously not technically feasible.

Our first product is the VELUM system, a solution for industrial laundries. Industrial laundries wash and dry textiles in a highly automated environment to cope with the large quantities of dirty linen. There are even machines for folding laundry. But they have one major drawback: Each machine requires an employee to feed the laundry spread out and without wrinkles.

That’s where our VELUM system comes in. sewts VELUM feeds towels into existing folding machines, closing this gap in automation. Our inhouse developed AI analyzes textiles and translates the findings into robotic commands. VELUM is optimized for adaptability and handles all towels up to 1x2m in size.

POSITIVE IMPACT ON THE SOCIETY

A company who believes in sustainability and prosperity through automation. Processes involving the handling or production of textiles are often performed far away from the place where the textiles are actually being used, requiring an enormous transportation effort. By automating these processes, we can move them back right to where they’re needed in a cost-efficient way. This way, we will shorten transportation routes, create more reliable supply chains, save CO2 emissions and tackle the issue of overproduction.

BENEFITS TO USE THE 3DEXPERIENCE PLATFORM

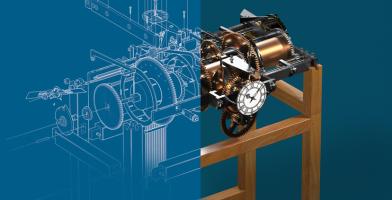

We are using the 3DEXPERIENCE platform in our development process by creating a virtual twin of our system, which ensures everyone in the team is working with a single source of truth. We also use the platform to perform FEM simulations. This allows us to simulate the behavior of textiles and generate synthetic image data for our AI models.

COLLABORATIVE & COLLECTIVE INTELLIGENCE

We are striving to continually improve our team collaboration and communication. Using tools like the 3DEXPERIENCE platform can support this goal, but even more important for us are our common company values and behaviors, development principles and our team organization.

Recently, we introduced an integrated product development process and created a cross-functional product team with both hardware and software development in order to facilitate smooth configuration management and to avoid problems due to dependencies between software and hardware in the development process.

PLAY 3DEXPERIENCE

Meet the team

-

Alexander Bley

Alexander Bley -

Tim Doerks

Tim Doerks -

Till Rickert

Till Rickert -

Ernst Waas

Ernst Waas -

Teresa Krebs

Teresa Krebs -

Prashant Doshi

Prashant Doshi

Similar projects

SYOS

IF WE tailor-make musical instruments, can we help musicians deliver a personalized sound?

3DVarius, the First 3D-printed Electric Violin

IF WE 3Dprint your own violin, can we play better music?

DRACULA TECHNOLOGIES

IF WE collect energy from light, can we make internet of things sustainable?

CHRONOSPEDIA

IF WE create a collaborative 3D encylopedia for clockmaking, can we ensure the saving and transmission of the antique knowledge?

Submit your project

Do you think your project is the next big thing?

Join the team !