FLEXPENSER

IF WE can open a package without opening it, can we reduce global liquid waste?

Flexpenser project is about an extremely low-cost and robust solution to eliminate the currently inevitable waste of different liquids due to contamination and oxidation. It relies on a decade of scientific research to develop a customizable mechanical unidirectional valve with unprecedented features.

WHY?

700,000,000 tons of liquids are wasted every year. Think of your favorite wine, milk or juice that have gone bad too quickly. Or the medicine that we have to throw away, the detergent we overuse, the sensitive chemicals we discard, or even too much blood we give for a clinical test that can be done with a drop of blood.

DISRUPTIVE INNOVATION

It’s a problem as old as the food and beverage industry: when you open a package, air and contaminants get in and spoilage occurs. It does not matter if you close the package again or where you put it after; it will spoil quickly due to contamination, oxidation or both.

After more than a decade of research, Flexpenser has developed a solution to delay this process: a unidirectional valve that allows for the opening of a package without actually opening it. Flexpenser’s technology is customized for every type of liquid packaging, providing universal airless and exact dosing solutions that protect the contents from contamination and oxidation– at the lowest cost. This will minimize liquid waste, eliminate preservatives, and protect the integrity of thousands of liquid and semi-liquid products.

POSITIVE IMPACT ON SOCIETY

This will include the packaging solutions for liquid and semi-liquid products and combined micro-storage dispensers for biomedical and laboratory devices. Flexpenser technology has a fundamental and systemic impact on both households and industries.

Flexpenser’s technology is applicable for both households and industry alike. That means their packaging solutions for liquid and semi-liquid products can be used in places like laboratories and biomedical settings, potentially becoming a game changer in those spaces. Their valve can extend the shelf life of liquid products without the use of preservatives. It can also minimize waste and CO2 consumption by reducing currently-necessary overproduction and distribution processes meant to offset eventual spoilage of goods. Their patented technology is also recyclable and reusable, and meets 3 UN Sustainable Development Goals.

BENEFITS USING THE 3DEXPERIENCE PLATFORM

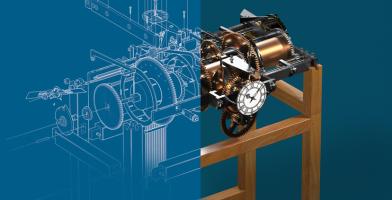

Flexpenser relies on customizing its technology for specific conditions. This requires access to modeling, simulation, and manufacturing software, and, in particular, fluid dynamic and fluid-structure-interaction simulation using CATIA. Apart from this, their team needs extensive knowledge and experience with the 3DEXPERIENCE platform to fine tune their designs and products.

COLLABORATIVE & COLLECTIVE INTELLIGENCE

Flexpenser is a values-based company that aims to solve one problem at a time through strategic partnerships with like-minded companies. Their technology requires customization for a specific range of liquid properties and operational conditions, which generates opportunities for creating collaborative and collective intelligence with their partners. Currently, Flexpenser has verified their solution with more than 15 leading companies in different industries, including FORTUNE 50 and FORTUNE 200 companies. Many of these companies are deeply interested in customizing Flexpenser’s technology for their products using their know-how and expertise. Currently, they have partnered with one of the world’s largest beverage companies and are finalizing several similar partnerships with the leading producers of home care, personal care and packaging companies in the field of pharmaceutical products.

Meet the team

-

Kewmars KazemzadehCEO

Kewmars KazemzadehCEO -

Giulia GaudenziCTO

Giulia GaudenziCTO

Similar projects

Submit your project

Do you think your project is the next big thing?

Join the team !