3DVarius, the First 3D-printed Electric Violin

lightweight, fluid design... and of course music !

IF WE 3Dprint your own violin, can we play better music?

Laurent Bernadac is an INSA Toulouse engineer, and a virtuoso musician as well (Medal at the Conservatoire de Toulouse, Jazz Guitar & Violin Section). Laurent had a challenge: design an electric violin which wouldn't weigh more than a classic, wooden acoustic one. After several trials, he found the solution: a 3D Printed Violin. He named his concept 3Dvarius.

The promise is now a success:

- A Kickstarter has been launched successfully.

- The first violins will are commercialized to customers all around the world since mid December 2016.

The feel of the classical violin

Let's come back on this success story with an interview with Laurent Bernadac.

-"Not every musician designs his own instrument. Tell us about yourself and what motivates you."

-"I’m 28 years old, I live in Toulouse and I’m a mechanical and energy engineer, as well as a professional violinist. I play the electric violin, and I was seeking a unique way to play it that differed from the classical violin, which I play as well. I wanted to take the electric violin in a new direction. I love to discover and invent new things, and I’ve always tried to improve details that bothered me in every violin I’ve tried, to add more lightness. I try to reproduce the feeling of a classical violin on an electric violin, which has a more powerful, pure sound. This violin was really a personal project, driven by passion, to create an instrument that reflects who I am. I spent three years designing it, because I wasn’t in a hurry and didn’t have any orders to fill, since the violin was for me. My training as an engineer at INSA Toulouse was obviously helpful."

-"What are your sources of inspiration?"

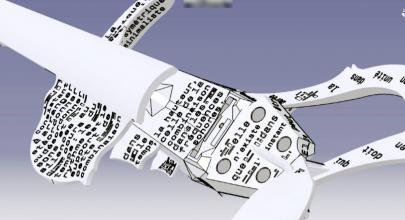

-"I’m inspired by all of my experiences, and when I am able to produce through precision and effort, by analyzing what works and what doesn’t. Aerospace and space technology were a major inspiration, in particular for the design aspects. The violin is quite sleek – I wanted it to be as inconspicuous as possible, so that it almost disappears behind the musician. Light, yet with a strong identity. That’s why it’s clear and has a few curved shapes similar to aerodynamic designs. In aerospace, we try to achieve solidity and strength, as well as reliability and lightness. I sought to do the same with my violin – the instrument had to have the least amount of material possible, with all the requisite characteristics in terms of strength."

-"How did the creation process unfold?"

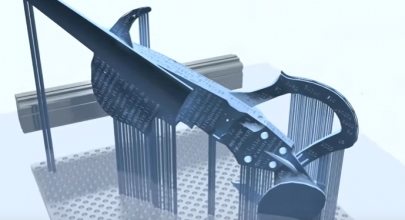

-"I used all sorts of digital resources. I did a lot of drawings, a lot of testing, and a lot of research on mechanics and sound waves. My school and former professors helped me a great deal and opened a lot of doors for me. I had originally wanted to make an aluminum violin, but the machining process used at that time unfortunately wasn’t able to produce the design I was looking for. I was also looking for transparency and aluminum was not suitable. In the end, I opted for polycarbonate. The 3D printing technique used is stereolithography, which offers precision as fine as ten microns. This technology uses a UV laser to polymerize photosensitive liquid resin. And I of course designed it on your amazing software: CATIA !"

Meet the team

-

Laurent Bernadac

Laurent Bernadac -

Pauline Henric

Pauline Henric -

The violin

The violin

Press

They´re talking about us:

Similar projects

SYOS

IF WE tailor-make musical instruments, can we help musicians deliver a personalized sound?

DRACULA TECHNOLOGIES

IF WE collect energy from light, can we make internet of things sustainable?

SEWTS GMBH

If we automate textile handling, can we make the textile industry more sustainable?

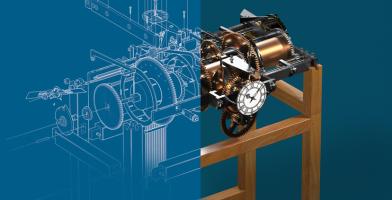

CHRONOSPEDIA

IF WE create a collaborative 3D encylopedia for clockmaking, can we ensure the saving and transmission of the antique knowledge?

Submit your project

Do you think your project is the next big thing?

Join the team !