IF WE collect energy from light, can we make internet of things sustainable?

Our daily usage of connected objects, smartphones and other devices requires more and more energy. Some studies show that there will be 41.6 billion connected IoT devices, or "things," in 2025.. The scale factor makes everyday a new challenge for the network to provide this overload of energy.

We are living in a world of light. Photovoltaic energy is available everywhere in the planet, being energy self-sufficient for our electronics is for all of us the really wireless world!

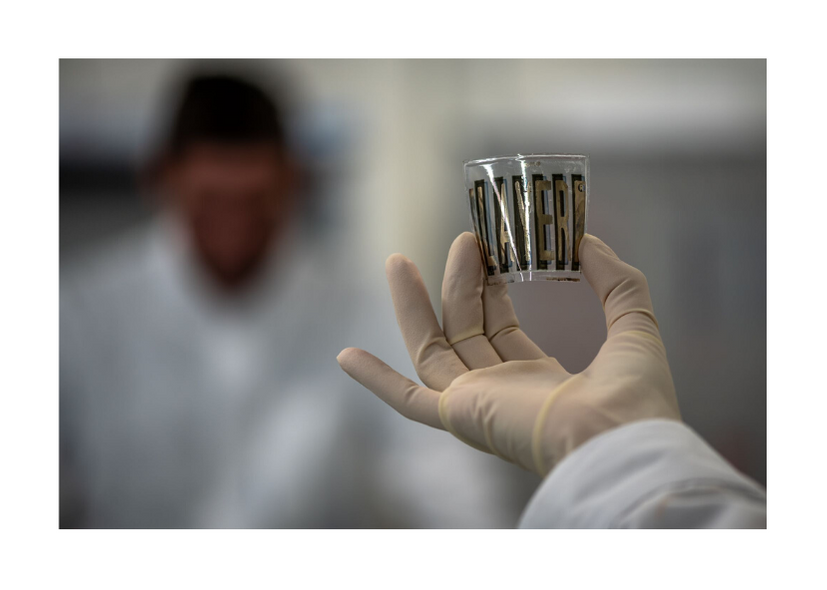

Manufacturing technique using digital printing opens new perspectives

BREAKTHROUGH IDEA

Products can be covered with cutting-edge photovoltaic cells to power sensors and or devices connected to the IoT. Taking advantage of the natural or artificial lighting allows for energy to be collected wherever you are in the planet, energy that can be supplied directly your electronics, or stored in batteries.

Dracula Technologies is developing a disruptive printable solar energy, called Layer®

This organic photovoltaic (OPV) cell manufacturing technique is made of 5 nano-layers of materials using digital printing; in the same way that an office printer uses graphic ink to print, Dracula prints its LAYER modules using conductive ink that they have formulated thanks to:

• Generating energy from ambient light (natural or artificial)

• Being adjustable and integrated in the surface thanks to the printing of the modules; shapes and curves make them possible

• Ensuring positive environmental impact. Only organic polymers derived from carbon are used to make the conductive inks

Technical expertise:

Dracula Technologies R&D teams have developed a support process using tools to evaluate energy consumption and lighting conditions. They then carry out studies in order to optimize the solution needed.

- Spy: The use of photodetector cells to carry out assessments and measure the lighting conditions.

- Characterization test bench: Reproduce exposure situations of our modules to different lighting conditions both indoors and outdoors.

- Modeling software: To guarantee made-to-measure sizing which optimizes the active surface in order to meet the clients’ needs precisely.

POSITIVE IMPACT ON THE SOCIETY

GOAL 3 : AFFORDABLE AND CLEAN ENERGY

Dracula Technologies ensures access to affordable, reliable, sustainable and modern energy for all. LAYER takes advantages of natural or artificial lighting to collect energy wherever you are.

.

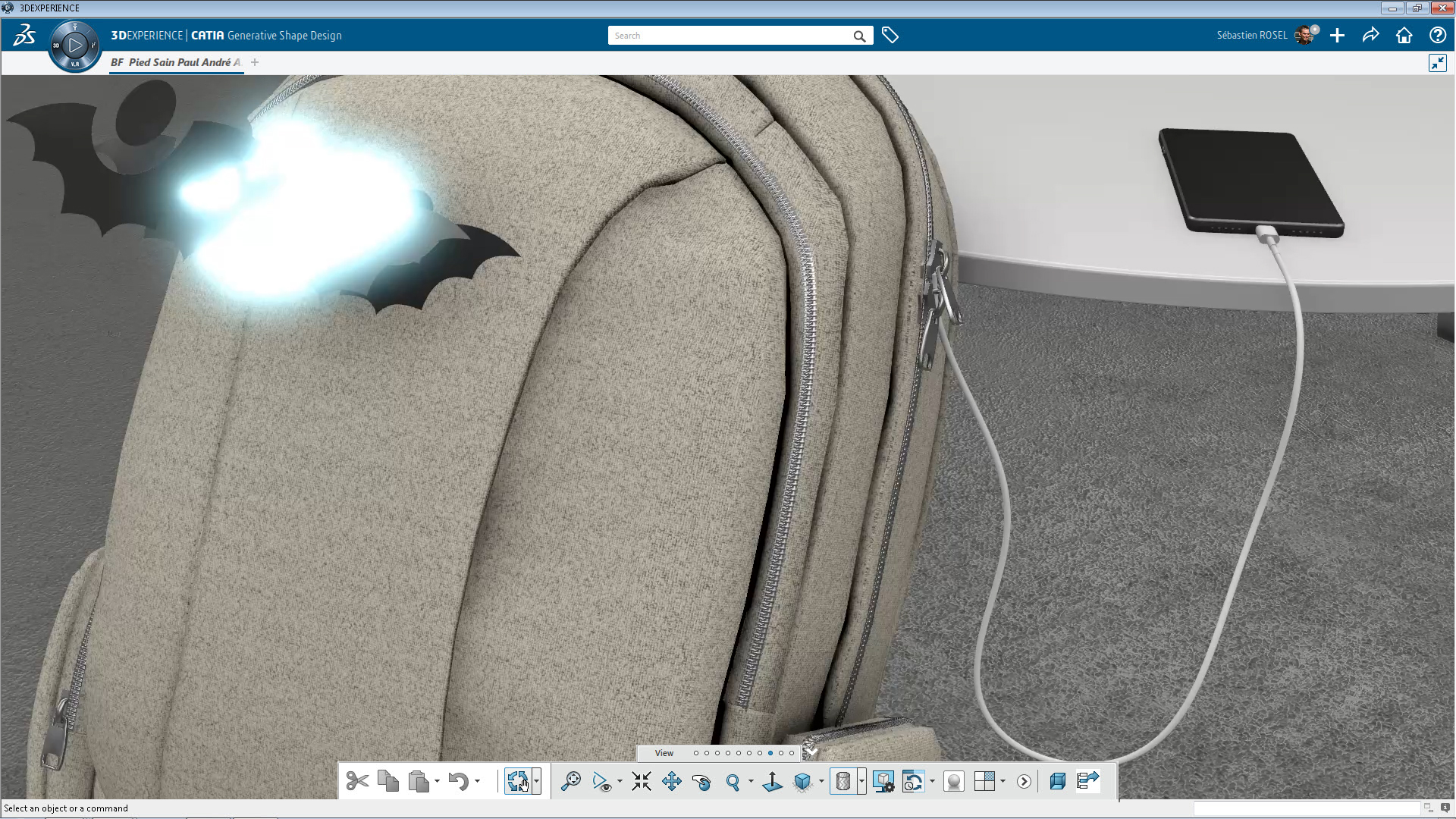

BENEFITS TO USE THE 3DEXPERIENCE PLATFORM ON CLOUD

Dracula Technologies has been involved in the 3DEXPERIENCE Lab program since 2017. They have adopted the 3DEXPERIENCE platform on the cloud for Chemistry, Simulation and Design Solutions.

Specifically, they:

- Use BIOVIA to help chemical formulation and material sustainability

- Implement a knowledge-based design tool to integrate in device, translate styling inputs into predictable energy, and create production data

- Simulate performance, robustness and durability

- Manage B to B relationships (test and evaluate of a design online) using the 3DEXPERIENCE Marketplace

COLLABORATIVE & COLLECTIVE INTELLIGENCE to Ensure Success

Dracula Technologies know-how is the result of a collaboration of over 10 years with the industrialists, HUTCHINSON and research centers (CEA-INES, CNRS, IM2NP, CiNaM, CSEM). Their development engineers work closely with the scientific committee.

Dracula Technologies carries the French Tech in the Alps, BPI Excellence, InnoEnergy, Dassault Systèmes and Airbus labels. Their technology has led to several patents and relies on the mastery of an OPV cell manufacturing process using digital printing to trap light both outdoors and indoors.

PLAY 3DEXPERIENCE

Meet the team

Similar projects

Submit your project

Do you think your project is the next big thing?

Join the team !