IF WE start eco-designing consumer goods, can we end planned obsolescence?

An alternative to the drifts of the programmed obsolescence. L’increvable is the idea of changing the way we design and consume products. Let’s take the example of a product you can find in quite every house: the washing machine. A washing machine average cost is 350€. It decreased across time, but the repair cost of the washing machine increased by 125% the last 20 years. So when a consumer needs to repair his machine, he is actually buying a new one because for quite the same price, he will have access to the latest technology, and will not face break for years.

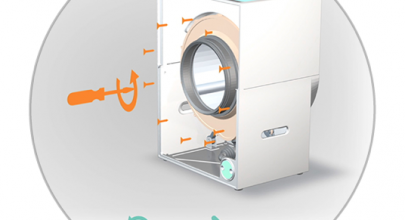

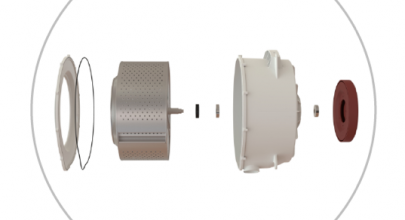

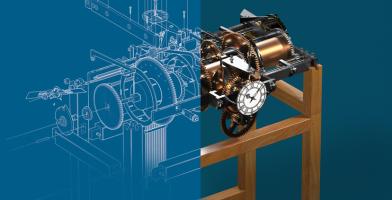

There is a solution: when you design your product, you actually anticipate the repair and the recycling of the product, to make it less expensive and more efficient. In more details, the principle is to make every piece removable, changeable, and recyclable. And this principle is not just for washing machine, it works for everything. It is called: Eco-design for End-of-life.

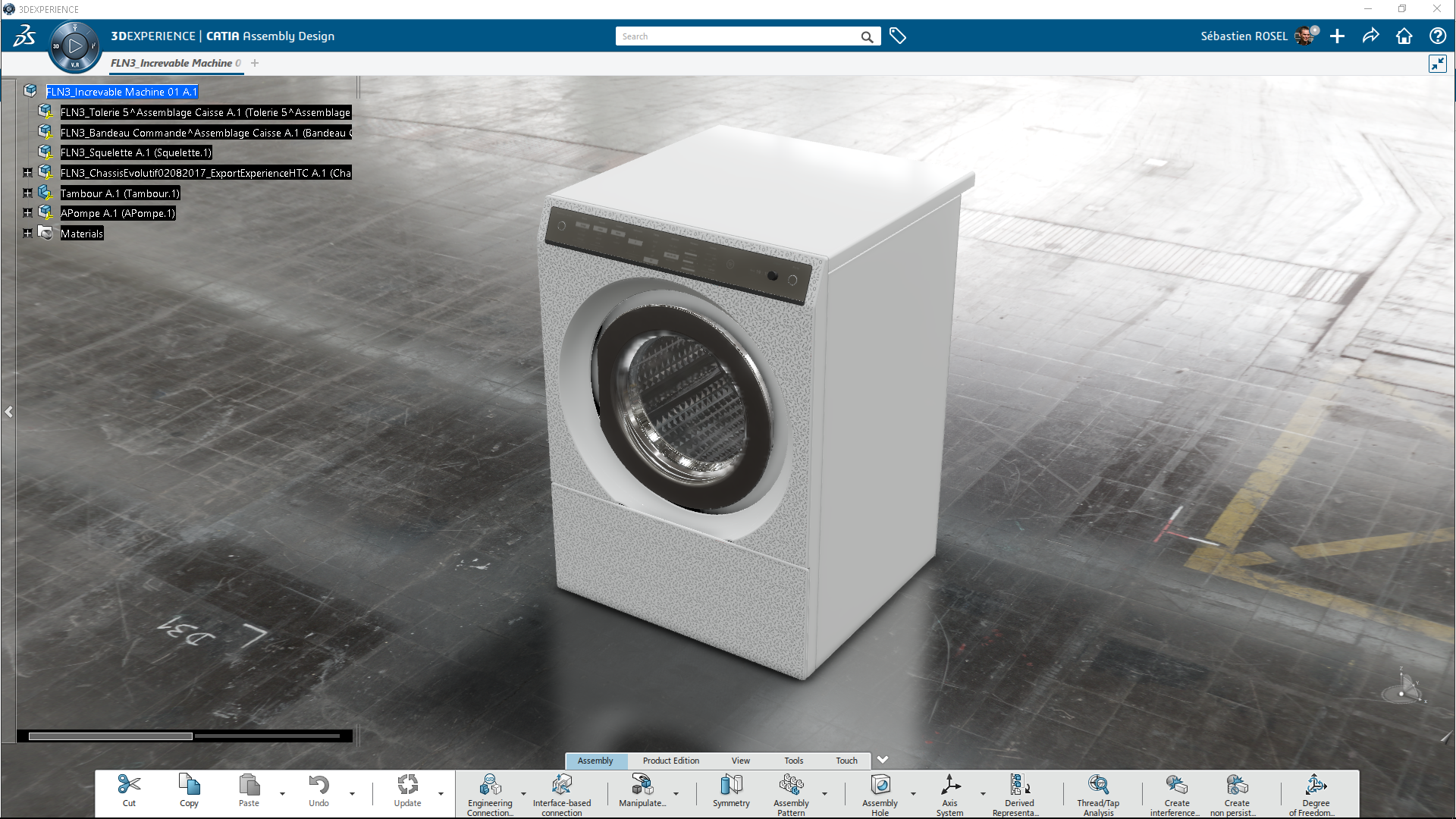

This french startup revolutionizes consumption patterns with a modular washing machine

AMBITION

Embody the alternative reference in the large public appliance business by offering reliable, repairable and scalable high added value devices.

L’increvable is a concept of an eco-designed washing machine, made by Julien Phedyaeff, then student at ENSCI. The device is fully reparable, parts can be changed for evolved ones, it is connected and opened to enable software updates and innovation, can be configured to face the look obsolescence issue.

DISCOVER in 360° video an alternative to the drifts of planned obsolescence

POSITIVE IMPACT ON THE SOCIETY

GOAL 12: Responsible consumption and production

L'increvable ensures sustainable consumption and production patterns.

Watch the video about Consumption Innovation by L'Increvable

Meet the team

Julien Phedyaeff, Christopher Santerre

contact@lincrevable.com

-

Christophe Santerre

Christophe Santerre -

Julien Phedyaeff

Julien Phedyaeff

Press

They´re talking about us

Similar projects

SYOS

IF WE tailor-make musical instruments, can we help musicians deliver a personalized sound?

3DVarius, the First 3D-printed Electric Violin

IF WE 3Dprint your own violin, can we play better music?

DRACULA TECHNOLOGIES

IF WE collect energy from light, can we make internet of things sustainable?

SEWTS GMBH

If we automate textile handling, can we make the textile industry more sustainable?

Submit your project

Do you think your project is the next big thing?

Join the team !