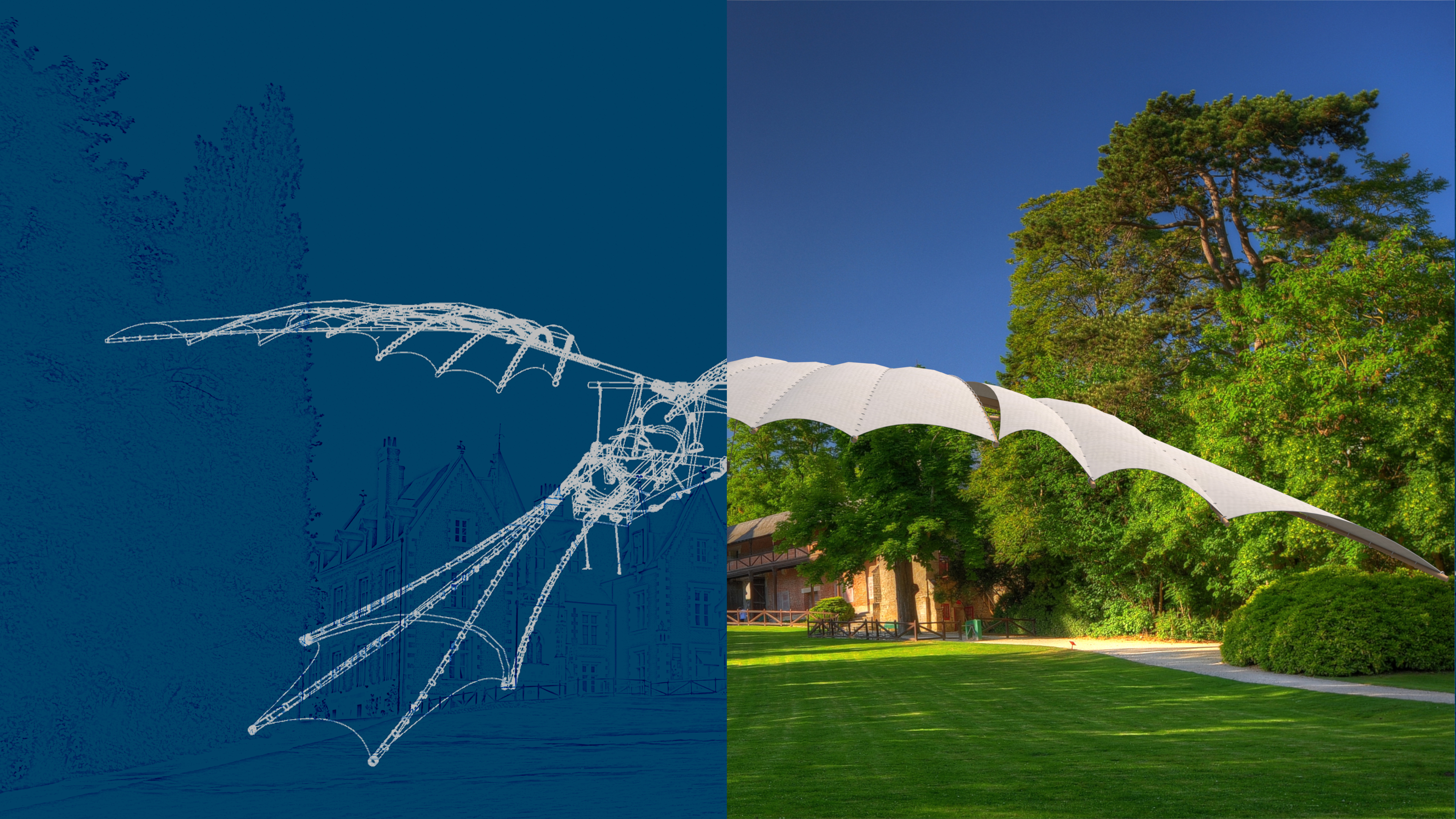

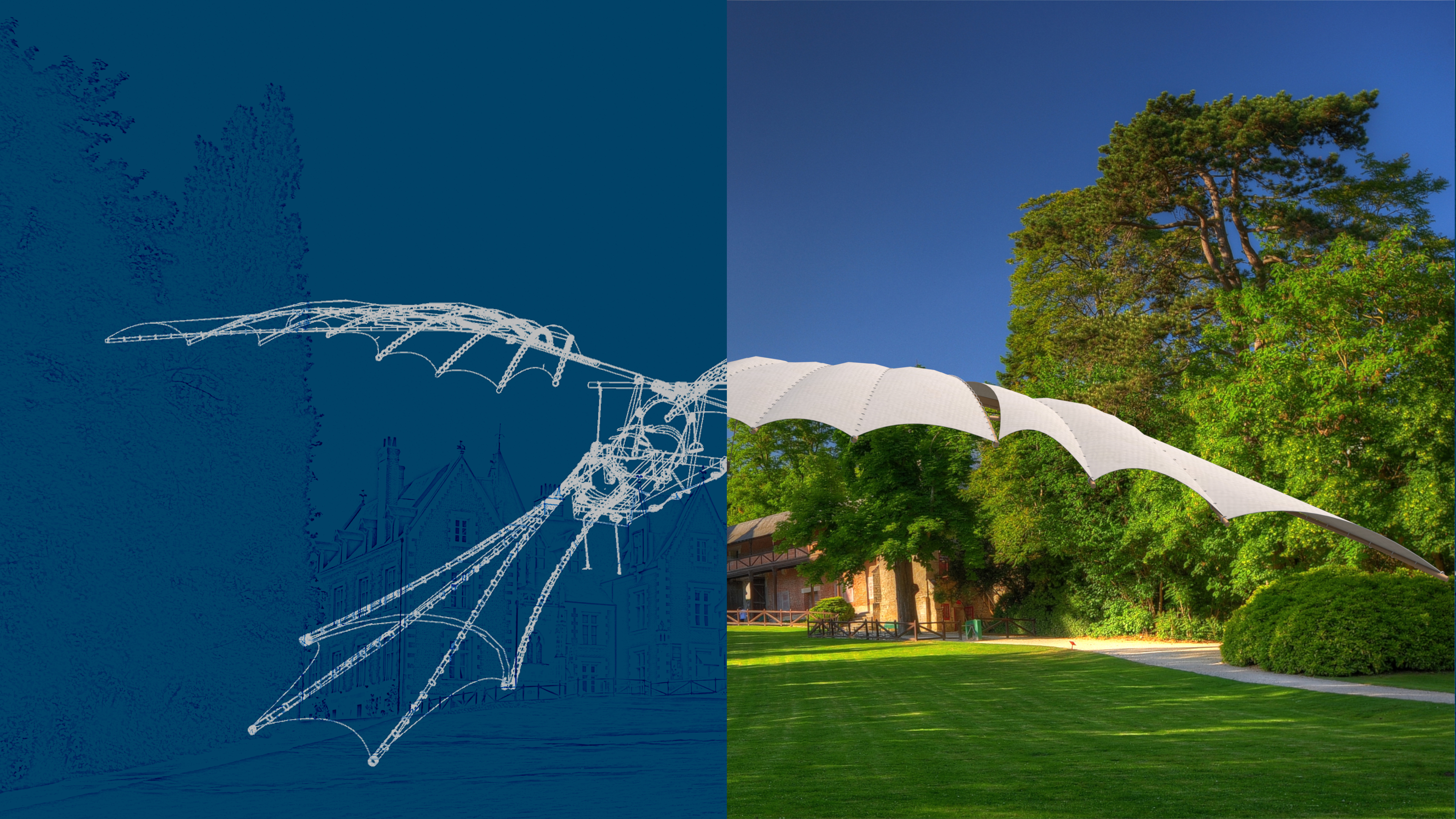

IF WE design Leonardo' machine in 3D, can we better understand the incredible patrimony he inherited?

Leonardo da Vinci, engineer. He is the father of inventions as modern as the plane, the helicopter, the submarine or the automobile. Made of wood in its time or even mostly sketched extremely detailed, these machines were then not often functional, but already demonstrated his genius. Today, most of his projects have been put into practice and are now used by the vast majority of men.

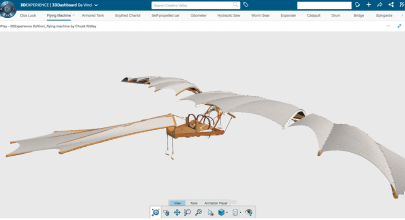

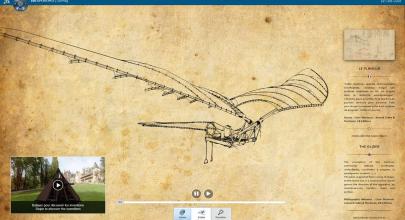

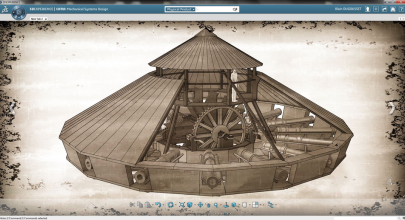

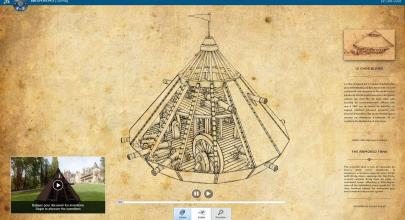

Welcome in this Open Innovation project, to digitally reconstruct in 3D Leonardo DaVinci invention from his codex and put them into 3D Experiences.

"All our knowledge stems from our sensibility" Leonardo DaVinci

With his innovative, engineering mind, passion for curiosity, Leonardo da Vinci had explored many areas of studies - inspiring artists, architects and engineers of all disciplines and industries (Aerospace & Defense, Transport & Mobility, High-Tech, AEC, Life Science, ...). He was able to look at the connection between multiple disciplines - combining Science with Art, Humanities with Technologies - was unique and key to his ability to invent.

The Open Innovation approach is bringing people from different background throughout the globe to share their knowledge. So if anyone can design Leonardo's machine in 3D, can we better understand the incredible patrimony he brought us?

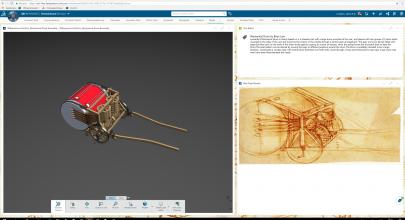

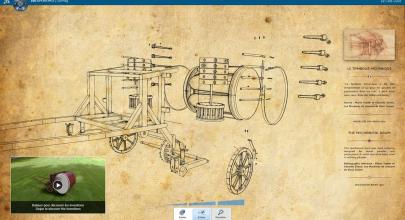

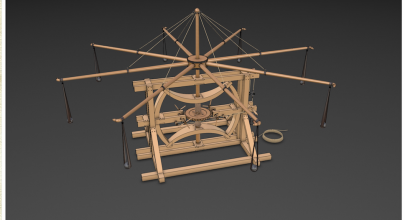

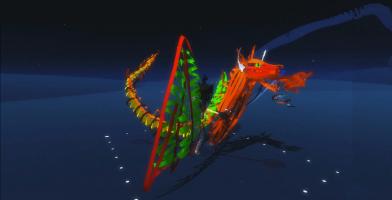

The initiative has started in 2012 to reconstruct in 3D the machines. Even though most of them were genuine visionary creations, some would not be working properly in real life. By complementing the intelligence and vision of the human mind to modern software and hardware tools, we can have those strange machines come to virtual life and simulate their behavior! The bet at that time was to empower collective intelligence to gather passionates and designers through the social community and let them work together to achieve the goal. We had fantastic results over the time such those projects done during those challenges and have revealed talents and power makers.

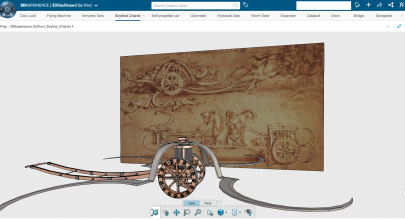

Chuck Ridley, an American passionate worked on Worm Drive, Brian Law, a British citizen did the Mechanical Drum, Antonio Camberos, from Mexico design the Scythe Chariot in 3D, Alain Dugousset from France made the complet detailed design of the Battleship and Thibault Waltzer, the winner of the contest 2014 mixed two Da Vinci Concepts to create the "Flying Pack". Antonio Camberos, Vinay Reddy, Aleks Marjanovic, Namkarn Munprasit, Josue Blanco, Juan Mauricio Zaleta have greatly contributed to this open innovation project too.

In addition, now the 3DEXPERIENCE platform with all kinematic, behavior, texturing, shading, ... the machines are available with our 3DPlay and in VR with Creative Experience. In large scale, you can immerse yourself in the experience of each machine. By a simple touch, you can live a dream.

Join our community to learn, discover and share knowledge of Leonardo’s works in Arts, Sciences and Technology. Become a contributor to this unique 3D Social Encyclopedia.

(Even if you are not an engineer), the inspirational work of Leonardo Da Vinci will open your eyes to a world of infinite possibility…

POSITIVE IMPACT ON THE SOCIETY

GOAL 4: Quality education

Open Codex ensures inclusive and equitable quality education and promote lifelong learning opportunities for all. This community was a perfect driver to prove that not only Wikipedia can work for collective crowdsourced projects but it can be applied also to science & technologies leveraging a rich media called 3D...

BENEFITS TO USE 3DEXPERIENCE PLATFORM ON CLOUD

Using the 3DEXPERIENCE Platform for design & engineering users are able to recreate Da Vinci sketches and turn ideas into 3D Experiences, develop the Mechanical and System concept in 3D, with Geometry and Kinematic. To live the experience of the machine, the 3D Play and Creative Experience has been the must to make it real and validate each innovation of Da Vinci.

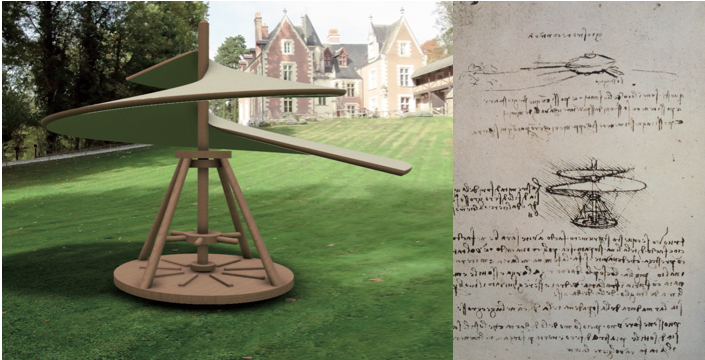

Look, this machine has been developed in the platform by Franck Lennon one of our key champion! It makes it real with its real environment at Clos Lucé Castle.

The Aerial Screw, how does it work?

The predecessor to the modern helicopter. Da Vinci's aerial Screw with a radius of 4.80 meters is made from linen stretched around metal wire. Its rotation is manually powered by turning wooden cranks around the central shaft or by the rapid unwinding of a cable around the shaft.

This Open Codex project could not work without the support of the partners we thanks, Scala Archives, Clos Lucé Castle, HP and AMD.

PLAY 3DEXPERIENCE

Meet the team

Passionate, experts, designers, engineers, Hobbyists, Historians, Mathematicians, FabLabs share Da Vinci’s innovations to experience 3D Machines in Virtual World, willing to contribute to an open innovation project.

-

Chuck Ridley

Chuck Ridley -

Brian Law

Brian Law -

Catherine Simon Marion

Catherine Simon Marion -

Franck Lennon

Franck Lennon -

Thibault Waltzer

Thibault Waltzer -

Antonio Camberos

Antonio Camberos -

Alain Dugousset

Alain Dugousset -

Sebastien Brugulat

Sebastien Brugulat -

Scala Archives

Scala Archives -

Vinay Reddy

Vinay Reddy -

Aleks Munprasit

Aleks Munprasit -

Namkarn Munprasit

Namkarn Munprasit -

Josue Blanco

Josue Blanco

Similar projects

Immersive Virtual Ideas Sharing

IF WE leverage the simplicity of VR, can anyone sketch ideas and bring them to life?

OPEN FRUGAL INNOVATION

If we harness the power of frugality and innovation, can we create a community that fosters resourcefulness, sustainability, and positive social impact through affordable solutions?

Submit your project

Do you think your project is the next big thing?

Join the team !