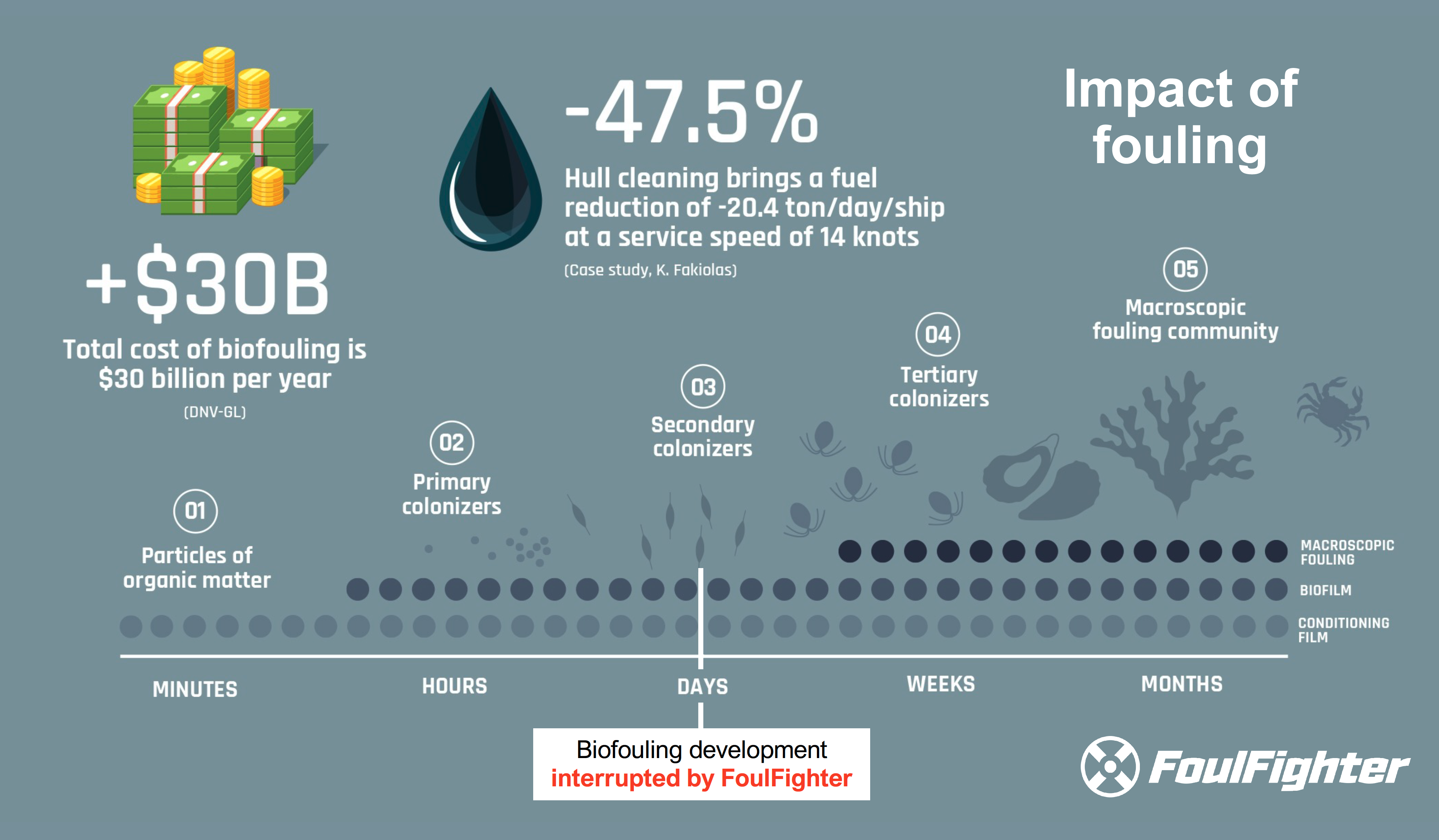

If we keep vessels clean from hull fouling, can we cut back on maritime transport CO2 emissions?

Fouling costs the shipping industry $30 billion each year, and maritime transport emits around 1,076 million tons of CO2 annually. Frictional resistance is also a factor, since even at an early stage, microbial sludge leads to a 10-20% increase in frictional resistance, and thus to greater consumption

Reduce the maritime transport CO2 emissions

BREAKTHROUGH IDEA

FoulFighter has developed a way to reduce environmental impact, while enhancing business for ship owners and operators. We cut back on maritime transport CO2 emissions, reducing the spread of invasive species and lowering the operational costs of ships by proactively attacking hull fouling. Our emissions-reducing, crew-friendly automated hull cleaning device proactively prevents the formation of marine growth and fouling organisms.

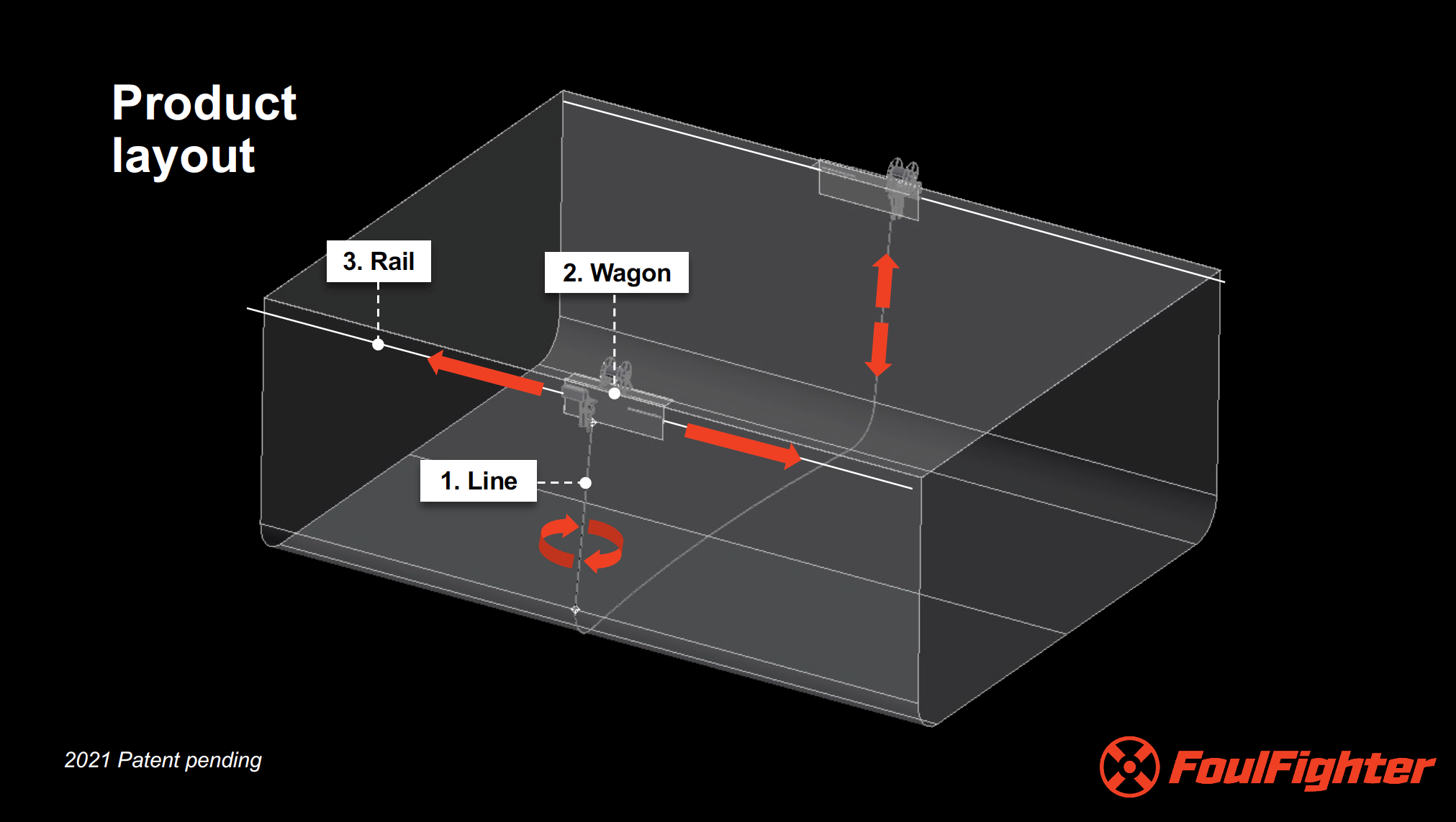

The FoulFighter solution consists of 3 major components:

1. A rail built on the side of the vessel or integrated with the side rail.

2. A wagon runs between the bow and aft to carry the line. The wagon has rotating and tightening systems.

3. The line has a cleaning function. To be efficient, it needs to have the correct pressure on the hull.

A user interface enables easy control and safe operation. Remote access to the unit is also routed through the user interface and its automation system.

POSITIVE IMPACT ON THE SOCIETY

FoulFighter is very committed to meeting the UN Sustainable development goals.

Goal 8: Reducing the need for divers working under the ship is a major improvement for their convenience and safety.

Goal 13: Reducing the emission of 1,076 million tons of CO2 annually as much as possible

Goal 14: Reducing the risk of invasive species and cutting the air and water pollution of shipping

Goal 17: We value diversity and seek partnerships to tackle this high-stake goal.

We also support the use anti-corrosion paints for our anti-fouling operations and eliminate the use of biocide paints.

BENEFITS TO USE THE 3DEXPERIENCE PLATFORM

FoulFighter finds it valuable to access design, simulation and collaboration tools from a single user interface provided by Dassault Systèmes. It helps us develop our product over its life cycle, from the first sketch to the effective production of systems for delivery to shipowners internationally. Taking full advantage of the digital prototyping tools is one area we are looking forward to exploring with a wider group of collaborators.

COLLABORATIVE & COLLECTIVE INTELLIGENCE

We have brought together people with experience from different fields that bring value to our proposition. Each core member of the team is passionate about cleaning up the seas and doing their part to meet the UN Sustainable Development Goals. Due to COVID-19, we have never met in person. Instead, we always work remotely, collaborating with online tools and meeting regularly to drive our physical product ideas forward. Now, our network will continue to grow naturally through the association with Dassault Systèmes, enabling us to work in ever wider circles and bringing in talent with additional expert skills.

Meet the team

Diverse international team with combined professional experience of over 200 years. Design and production resources are internal or external through long term partners.

-

Mika Koli

Mika Koli -

Teppo Lainio

Teppo Lainio -

Kim Roukus

Kim Roukus

Similar projects

XtreeE: Additive Construction

IF WE use robot to 3Dprint your building, can we optimize your living space?

XSUN

If we survey the earth with a network of flying sensors, can we better optimize the human activity?

GYROLIFT

IF WE have an innovative mobility solution designed for all, can we get rid of wheelchair stigma?

Submit your project

Do you think your project is the next big thing?

Join the team !