IF WE recycle waste on site, can we turn it into resources?

The world is pivoting away from fossil fuels and is increasingly aware of the amount of waste generated and, sadly, not yet feasibly recycled. Mixed waste streams are burned or landfilled. In some parts in SEA, waste is still burned in open fires. AES wants to be a part of the solution.

Plastic and mixed wastes are mostly landfilled or burned. Only about 30 % of plastics inside the EU are truly recycled. The old concept of collecting waste and processing it centrally seems outdated. With developing countries catching up to the plastic production of first world countries and the need for improved recycling, new strategies have to be generated.

Small-scaled recycling plant

BREAKTHROUGH IDEA

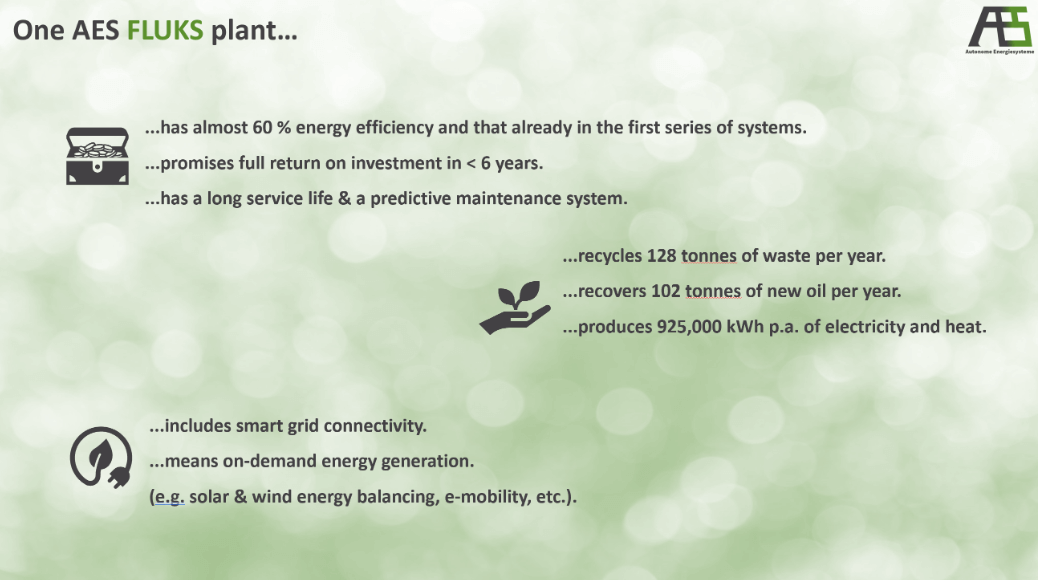

The AES FLUKS is the first plant generation of new waste processing systems. At temperatures of 500-550°C, the organic structures get decomposed into gas, oil and ashes. The oil will be used for heat and electricity generation, while the gases are burned for the energy consumption of the plant.

While the first plant series will be burning the oil for electricity and heat, our overall goal is to form an infrastructure for oil recycling. That is being accomplished by recovering the produced oil instead of burning it. Once the change from electricity generation to oil recovery becomes feasible for our customers, we can dismantle the generator, acquire the oil and get to an improved circular economy.

The AES FLUKS is made for very small waste stream quantities (100-350 kg/day), will be fully automated and controlled via the internet. While the waste is processed directly when it is put into the AES FLUKS, the oil can be stored and saved. Through the usage of local heat and electricity, the AES FLUKS reaches levels of efficiency far higher than normal waste processing systems.

The AES FLUKS comes in three different sizes - small, medium and large - catering for waste streams between 100-350kg/day. Starting at a price of 119.000 €, the AES FLUKS will be payed of with the savings in 3-6 years, depending on the customers waste stream.

A retirement home for example saves up to 50 % of the waste disposal costs, 15 % of electricity and 10 % of heating costs.

POSITIVE IMPACT ON THE SOCIETY

They want to address these challenges by a new waste processing design that recycles the waste, where it is produced.

BENEFITS TO USE THE 3DEXPERIENCE PLATFORM

AES is currently working with Project Planning, Part Design, Electrical Systems Design, and Fluid Simulations.

The benefits to use the platform are manifold. The easy collaboration, the simple assignment of roles and apps to team members and the marketplace with many standard parts makes the 3DEXPERIENCE platform a very powerful tool for them.

COLLABORATIVE & COLLECTIVE INTELLIGENCE

Through their shared private and professional experiences, they harmonize very well as a team and find a sophisticated and suitable solution even in stressful situations.

They have set themselves the goal of finding solutions to current issues in waste disposal and energy supply.

In doing so, they rely on innovative methods that correspond to the latest state of the art in the fields of process engineering, electrical engineering and control engineering.

PLAY 3DEXPERIENCE

Meet the team

-

Marco KarberCEO

Marco KarberCEO -

Jonas BonusCFO

Jonas BonusCFO -

Andres SheldrickCTO

Andres SheldrickCTO -

Lennart JacobsenStrategic Orientation

Lennart JacobsenStrategic Orientation -

Ulrich SchulteBusiness Angel

Ulrich SchulteBusiness Angel -

Jonas DickeIT and Steering

Jonas DickeIT and Steering -

Christa KarberBack Office

Christa KarberBack Office -

Cedrik HohenschueBachelor Student

Cedrik HohenschueBachelor Student

Similar projects

XtreeE: Additive Construction

IF WE use robot to 3Dprint your building, can we optimize your living space?

XSUN

If we survey the earth with a network of flying sensors, can we better optimize the human activity?

GYROLIFT

IF WE have an innovative mobility solution designed for all, can we get rid of wheelchair stigma?

Submit your project

Do you think your project is the next big thing?

Join the team !